To learn more, visit https://srmarms.com/.

To buy on GunsAmerica.com, click this link: https://www.gunsamerica.com/Search.aspx?T=SRM%20Arms%201216.

Shotguns have strengths that no other platform can rival. With the right ammunition, they can land shots at 100 yards, or bring down flying game. In the home defense arena, shotguns can be a formidable tool for a homeowner against a criminal. However, shotguns have always suffered one common weakness: Capacity. Although substantial when measured by either weight or diameter, the amount of ammunition that can be loaded into the gun is limited. Not even the best reloading technique can bring the shotgun’s staying power to the level of a detachable box magazine-fed weapon. Right? Wrong. SRM Arms has stepped up to the plate to take a swing at solving the capacity and reloading problems inherent in a 12-gauge shotgun with its semi-automatic Model 1216.

Rails on three sides above the magazine and barrel serve as a heat shroud as well as a mounting point for accessories.

SPECS

- Chambering: 12 ga., 3 inch

- Barrel: 18 inches

- OA Length: 32 inches

- Weight: 7.25 pounds

- Stock: Polymer

- Sights: None

- Action: Semi-auto

- Finish: Matte black

- Capacity: 16

- MSRP: $1,799.95 (priced on GunsAmerica.com around $1,500)

Unboxing the 1216

I wish that I could say that my thoughts were something more profound than “wow they got a lot of gun in a small box” when I opened up the 1216. I could quickly see that their approach to a shotgun that would hold 16 rounds of ammunition was unique. I at first questioned the execution but was excited to see someone pushing the design envelope in a genuinely innovative way, rather than putting sprinkles on the newest trend. The box contained the shotgun with one rotary magazine attached and a second rotary magazine sealed in a plastic wrapper. When I picked the gun up I was actually surprised at how light the package was. I was expecting something topping the scales at over 10 pounds, as most of these types of shotguns tend to be heavyweights even before being loaded with larger quantities of ammunition. It, in fact, weighs in at a mere 7.25 pounds.

The SRM Arms Model 1216 packs in a lot of firepower into a reasonably compact package. The semi-auto shotgun holds 16 shells of 12 gauge ammo.

A Unique Approach

This gun was clearly designed from the ground up to be what it is. By that, I mean that this is not just another basic gun with a good idea bolted onto it. Oftentimes we find these new innovative features duct-taped onto last year’s hardware, and the resulting project resembles some kind of Frankenstein’s Gun. Not the case here; all the parts look like they belong.

The design is ergonomic and compact especially, considering that it features a detachable magazine with a 16-round capacity. While this gun is technically a “bullpup” design, at first blush it appears to be a hybrid kind of quasi-bullpup design. This is somewhat of an illusion as the one-piece stock also serves as a shroud to conceal the hammer and recoil springing mechanism. I believe that the pistol grip is mounted a little further forward than on most bullpup designs to facilitate recoil control.

The shooter’s support hand here is located far forward ready to engage the dual levers (forward of his thumb) that allow the revolving magazine to be rotated.

The semi-auto action of the gun feeds in a unique way: With a rotary magazine. The rotary magazine features four, four-round tubes. The action locks open when empty on one tube, then you press down on the ambidextrous release button at the front of the tube to allow you to then rotate to the next tube (either clockwise or counterclockwise; your choice), which automatically releases the bolt to feed the next shell from the fresh tube into the 3-inch chamber. As a result, you can quickly fire all 16 rounds from the shotgun.

How Does It Work?

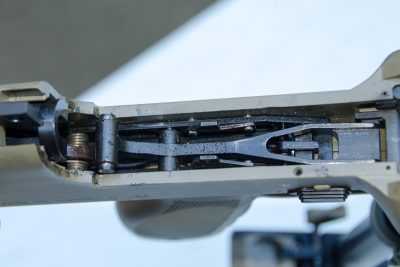

The action features a roller-delayed fast-cycling bolt that (I believe) works to reduce the felt recoil significantly. Okay, for all you gun geeks, the 1216 borrows the roller delay locking system from the HK design; and now for the normal people in the audience, this is a recoil-operated shotgun. The Model 1216 shotgun is held together with pushpins again clearly inspired by an HK, allowing easy access to the internals of the shotgun.

The 1216’s bullpup design allows the standard 18-inch barrel to fit in a platform that is only 32.5 inches in overall length. SRM Arms has avoided the horrendous triggers found in almost all of the bullpup-designed firearms; this one breaks at just over 6½ pounds. They accomplished this through a very unique design that resembles the hammer and bolt arrangement on an AR-15. The hammer is mounted in the center and comes up behind the bolt. This keeps the hammer closer to the trigger than a more “traditional” bullpup thereby eliminating the need for a long trigger linkage bar. The bolt impacts an upside down U-shaped buffer mated to the dual recoil springs below it. The sear actually sets behind the hammer as it does in an AR-15.

The shotgun features a reversible ejection port system to allow left-handed shooters to also use the 1216.

One drawback to the bullpup design is that it can sometimes leave left-handed shooters at a major disadvantage. The folks at SRM have mercifully resolved this, and made this a fully ambidextrous gun: The selector switch, bolt, charging handle, bolt release and ejection port can be moved to either side. I will acknowledge that the gun can be fired left-handed without changing the parts over. Your cheek weld is far enough back on the gun it does pelt the shooter with spent casings. However, it is a bit unnerving as you are quite close to the ejection port. It is probably best just to swap things over it needed.

Loading the magazine is accomplished fairly simply by removing the magazine by pressing a release button on the forward face ahead of the magazine tubes and pulling down the cylindrical magazine assembly from the front, out and away from the body of the shotgun. Simply insert rounds into the rear of each tube using your thumb to seat them behind the metal hook that keeps the rounds in the magazine tubes.

One issue that must be understood with this platform is that to load the chamber and bring the total round count up to 16+1, it requires that the magazine be inserted and then a round chambered. You may then safely remove the magazine and replace the round in the tube that is now chambered in the gun.

Also, unlike other more conventional shotguns, there is no “topping off” of the magazine tube(s) while it is in place on the gun. Think of it like a pistol or rifle detachable box magazine: Once you have fired a few rounds, if you want to add ammunition you have to change magazines (my sample came with two) or remove the magazine and refill before inserting again. There is no port or opening for single-feeding rounds into a tube (like with a tubular-magazine shotgun) while you are running the gun. Basically, you give up the ability to stoke up the gun while firing in exchange for having 16+1 rounds onboard.

Rotating the magazine is accomplished by engaging either of the dual levers forward of the magazine tubes located to rear of the railed front sight block assembly/magazine release button housing. Once the release lever has been activated, the magazine can be rotated in either direction based on shooter preference or need.

The gun is made from high-quality materials. The barrel is hammer forged, and all of the accessory rails are metal on the receiver. The forward rails that act as a shroud for the barrel are the same polymer that the buttstock and pistol grip are made from. I am not sure the exact composite of the materials but it appears to be some type of glass fiber reinforced polymer. I have no concerns that this would be anything other than durable.

The sample that I received had no sights or optics attached, but it featured more than enough Picatinny rails, integrated into three sides of the handguard, for one to attach all manner of optics, sights, lights or another tactical must-haves.

You Can’t Have It Both Ways

A very long time ago, I was taking a course from Mas Ayoob while he was in the process of testing a completely new pistol design. He quite generously handed the pistol around and gave everyone in the class a chance to shoot it. I’m still not quite sure whether we broke it or just exposed a malfunction. Either way, I railed hard against the pistol. After patiently sitting through my complaints, he asked me “How long do you think it took to de-bug the 1911 you’re carrying right now?” This experience sticks in my mind as a demonstration of the fact that most innovative ideas do not spring from the ground fully formed, and this does not make them bad ideas.

Whenever I get a gun to test, I always try to put it in the hands of multiple shooters. This helps me to garner as much information as I can and has the bonus of allowing me to share the wealth of shooting a new gun. I have observed that the shooting community wants, above all things, absolute perfection at rock bottom prices … and then laments that everything looks the same.

New designs in early stages of execution have oftentimes not been exposed to every potential circumstance or risk. Nor can manufacturers be expected to foresee every development, good or bad, in ammunition. I’m not trying to be an apologist here—I’m just saying that we need to stop eating our own if we want any new platforms to grow!

A Plan – Testing Methodology

I decided on a few key points about this shotgun that my testing should drive to define. First, reliability; what ammunition, if any, will this gun reliably function with? Second, manual of arms; is this gun easily usable in the hands of a novice shooter with a small amount of instruction? Third, shootability; can this gun be deployed in a fight, accurately fired, and will it beat the user to death? Finally, durability; will this gun stand the test of time, or will it shoot itself to pieces? What kind of maintenance will it require in its lifetime?

In an attempt to answer these four questions, I have assembled a gaggle of new shooters who are going through their very first shotgun qualification. I have also piled together all manner of loads, ranging from light trap to the most robust 3-inch magnum slugs that I could find. The SRM 1216 would get the gauntlet treatment.

At the Range

As I mentioned above, I went to the range to teach 14 people a basic familiarization and qualification with the Remington 870 shotgun. Once the initial teaching and qualification was out of the way, I brought out the SRM Arms Model 1216. I took about five minutes to provide a familiarization with how the gun functioned, loading the magazines, and inserting and rotating the magazines. I then let the students load their own magazines with the ammunition of their choice and have at it while I observed.

Five of the class members volunteered to take a turn on the 1216 shotgun. I went over the controls, loading the magazine and how to operate the magazine when necessary to rotate to the next position. I had two magazines and I requested that each tube be loaded with the same type of ammunition so that we could identify any issues without that extra variable.

The most common mistake among the shooters was rotating the magazine first one way and then the other—this resulted in rotating to an empty tube and not feeding more ammunition. This was usually a one-time affair and became relatively self-correcting.

[one_half]

[/one_half]

[one_half_last]

[/one_half_last]

All of the shooters liked that the bolt locked open on an empty chamber and closed when the magazine was rotated and a round had been fed automatically onto the feed ramp. The mechanics are simple: when the gun runs dry, you rotate the magazine and pull trigger. Simplicity is golden when it works.

Another fairly common observation was how soft-shooting the gun was. I attribute this to the thick rubber buttpad and the recoil-absorbing tendency of the polymers used in the body of the gun.

There is one quirk that became apparent early on: for this gun to reliably function it needs a heavy load, somewhere north of 1 1/8 oz. Almost anything less than that will result in the action failing to fully cycle. I think this is a byproduct of the delayed roller action that they have chosen to use. Once this problem was figured out, the gun ran with absolute reliability.

Did It Meet Expectations?

Somewhat similar to a revolver, the rear of the magazine features notches to facilitate rotation and locking.

Overall, this gun met or exceeded all of my expectations. Once the code was cracked on ammunition selection, reliability was no longer a question. The manual of arms seemed to become a non-issue after about 50 to 60 rounds were run through the gun. This gun is so unique among shotguns that I feel one would have to commit to the platform exclusively if they intended to employ it as their shotgun for serious purposes—and I could see myself putting that time in. In terms of being able to bring this gun to a fight, there is no question; this is one angry beast when it is fully unleashed. The compact package is easy to store and quick to deploy, both with and without a sling. You have the ability to instantly mount sights, optics and lights that will allow you to bring the heat in almost any conditions. In terms of durability and maintenance, I got no hint that this gun was sensitive to either one of these issues- and we quite literally ran it until no one wanted to shoot my ammunition anymore!

Once released, the rotary magazine is pulled down and away from the front to release it from the firearm for reloading.

This basic platform could allow you to choose different kinds of ammunition in each magazine such as slugs in one tube of the magazine with buckshot in another magazine. However, I don’t know that I would ever recommend depending on knowing which tube was loaded with what round then being able to select them under stress.

The folks at SRM have taken this platform to all of the must have variations. They have a less lethal kit that with a quick change of the bolt is capable of firing beanbag rounds. They have developed short barrel versions with a choice of 8- or 12-inch barrels and matching magazines. Oh, they also have a select-fire, closed-bolt version that I would be more than willing to test and evaluate! They even offer a California compliant version that uses a magazine lock release that requires a tool to remove and attach the magazine. Unlike the aftermarket “magazine locking device,” the SRM California compliant 1216 magazine lock is manufactured as a part of the shotgun. It is not an aftermarket system. Because each tube only holds four rounds and then requires a manual rotation it does not exceed the 10 round restriction.

Is It Worth It?

Over the years, I have looked at every specialty shotgun made, and I have always rejected the Street Sweepers, SPAS 12s, and too many others to mention. I never felt like they represented a usable and durable package. With a retail price of just under $1,500 on GunsAmerica.com, this may be your ticket if you are looking to be able to bring large amounts of firepower to the fight.

To learn more, visit https://srmarms.com/.

To buy on GunsAmerica.com, click this link: https://www.gunsamerica.com/Search.aspx?T=SRM%20Arms%201216.